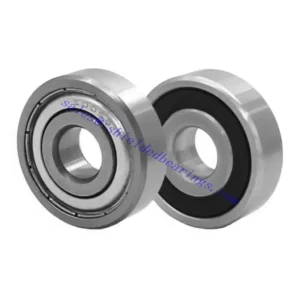

Iron shield bearing 20*42*12MM 6004

As one of the shielded bearings manufacturers, suppliers, and exporters of mechanical products, We offer shielded bearings and many other products.

Please get in touch with us for details.

Mail:[email protected]

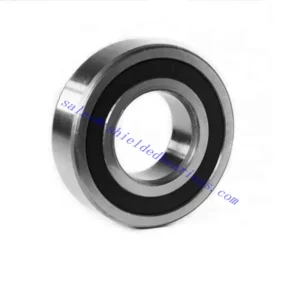

Shielded Bearings

Shielded bearings are an essential component in many mechanical systems, providing a reliable and efficient means of supporting rotating shafts and reducing friction between moving parts. These bearings are designed with a protective shield or cover that helps to prevent contamination from dust, dirt, and other debris, while also providing additional protection against moisture and other environmental factors.

One of the key advantages of shielded bearings is their ability to reduce maintenance and downtime. The shielded design helps to keep contaminants out of the bearing, reducing the risk of damage or wear to internal components. This can help to extend the life of the bearing and reduce the need for frequent maintenance or replacement.

Another advantage of shielded bearings is their high load capacity and durability. These bearings are designed to withstand heavy loads and high speeds, making them ideal for use in a wide range of industrial and mechanical applications. They are often used in machinery such as electric motors, pumps, and conveyor systems, where they can provide reliable and efficient operation even in demanding environments.

Shielded Bearings Specifications

|

ID

|

20mm

|

|||

|

OD

|

42mm

|

|||

|

H

|

12mm

|

|||

|

Sealed

|

Open,nylon/phenolic,metal

|

|||

|

Samples

|

available

|

|||

Shielded Bearings Benefits

Increased durability: Shielded bearings are more durable than open bearings because they are protected from contamination and moisture. This can extend the bearing's life and improve its performance.

Reduced maintenance: Shielded bearings require less maintenance than open bearings because they are less likely to become contaminated or damaged. This can save you time and money in the long run.

Improved performance: Shielded bearings can improve the performance of your equipment by reducing friction and vibration. This can lead to increased efficiency and productivity.

Uses of shielded bearings

Machinery: Shielded bearings are commonly used in machinery, such as conveyor belts, motors, and generators. They help to protect the bearings from dust and other contaminants, which can extend the bearing's life and improve its performance.

Vehicles: Shielded bearings are also used in vehicles, such as cars, trucks, and buses. They help to protect the bearings from road dirt and debris, which can extend the bearing's life and improve its performance.

Industrial equipment: Shielded bearings are also used in industrial equipment, such as pumps, compressors, and turbines. They help to protect the bearings from harsh environments, such as high temperatures and corrosive chemicals, which can extend the bearing's life and improve its performance.

Maintenance tips for shielded bearings

Inspect the bearings regularly for signs of wear or damage. Look for cracks, dents, or other signs of physical damage. Also, check for excessive wear on the bearing balls or races.

Lubricate the bearings regularly with a high-quality bearing lubricant. The type of lubricant you use will depend on the type of bearing and the environment in which it is used.

Clean the bearings regularly to remove dirt and debris. You can use a mild solvent or degreaser to clean the bearings. Be sure to dry the bearings thoroughly after cleaning.

Replace the bearings if they are damaged or worn. Do not attempt to repair damaged bearings. Replacing the bearings is the best way to ensure the long-term performance of your equipment.

We are one of the best shielded bearings manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!